Social Media Means

Social Media Means

Social Media Means

Social Media Means

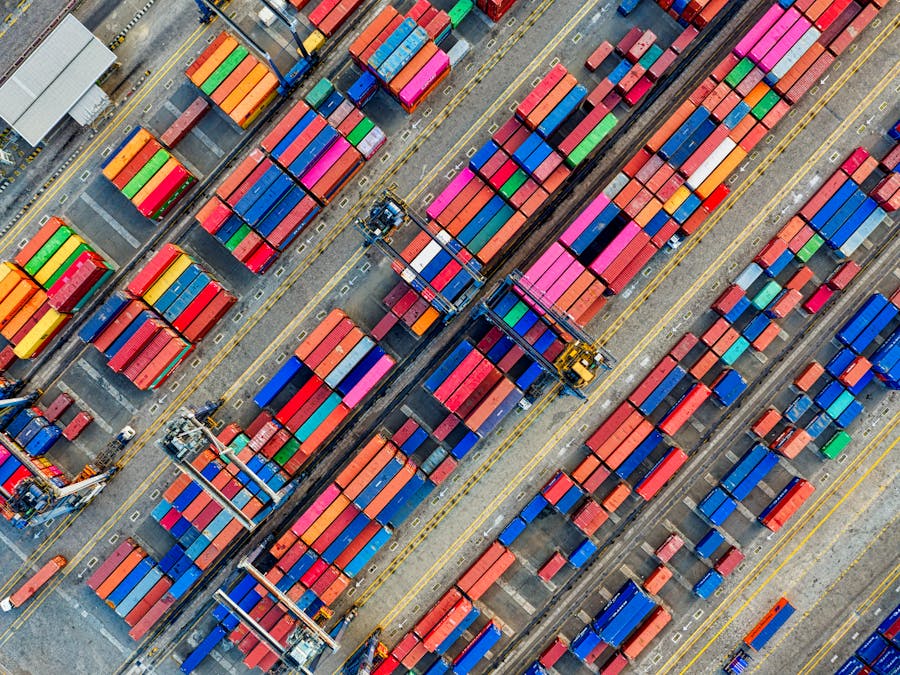

Photo: Johannes Plenio

Photo: Johannes Plenio

Let's explore the ground principles of Lean Six Sigma. Focus on the customer. ... Map the value streams to understand the work process. ... Manage and improve the process flow. ... Remove non-value-added steps and waste. ... Manage by fact and reduce variation. ... Involve and equip people in the process. More items...

Digital marketing can be broadly broken into 8 main categories including: Search Engine Optimization, Pay-per-Click, Social Media Marketing,...

Read More »

You'll be paid once your balance reaches $100. Say it takes approximately 1,000 video views to earn $4 from those viewers who saw ads. You would...

Read More »Lean Six Sigma is based on a set of principles that are a combination of Lean methodology and the Six Sigma approach. While Lean focuses mainly on eliminating wasteful activities, Six Sigma aims to improve quality by removing causes of defects. Indeed, both approaches share similar methodologies, values, and tools, which is one of the main reasons why Lean Six Sigma was born. Lean Six Sigma gets the best of the two worlds and provides a new way for organizational culture changes.

Google AdSense AdSense has a large advertisement pool that pays well, but its approval system is quite strict. Publishers get 68% of the revenue,...

Read More »

Absolute Temperature 0 K = -273.15oC = -459.67oF. The Kelvin (K) is the official metric unit of temperature. ... T = Tc + 273.15. Here is the...

Read More »The idea of eliminating waste originates from the Toyota Production System. Taiichi Ohno, who is considered one of the fathers of TPS, dedicated his career to building a solid and efficient work process. In the world of Lean, waste means “non-value-added activity”. Mr. Ohno himself describes what Toyota does with the following sentence: "All we are doing is looking at the timeline, from the moment the customer gives us an order to the point when we collect the cash. And we are reducing that timeline by removing the non-value-added wastes." Eliminating wasteful activities can help companies dramatically improve their operational efficiency, optimize resources and increase profitability.

the Google Play Store Donald Trump's social-media app Truth Social is live on the Google Play Store. Oct 12, 2022

Read More »

Yes, in the global world, it is possible, feasible and advisable to have multiple careers! You may wonder that you are unable to justify one career...

Read More »

1,000–10,000 followers = Nano-influencer. 10,000–50,000 followers = Micro-influencer. 50,000–500,000 followers = Mid-tier influencer....

Read More »

88 Social Media | Types of Social Media Tools Twitter (social networking tool example). Facebook (social networking tool example). YouTube (media...

Read More »

Learning to delegate appropriately is one of the hardest leadership skills to learn. It involves elements of some of the other skills, particularly...

Read More »

Micro-influencers (between 1,000 and 10,000 followers) make an average $1,420 per month. Jul 23, 2021

Read More »